The pin assignment concerning clock/direction signals of our complete range of controllers and control programs is preset and fix and cannot be modified. For any kind of controllers and motor drivers with a different pinning we can supply small cable adapters for a corresponding and correct assignment.

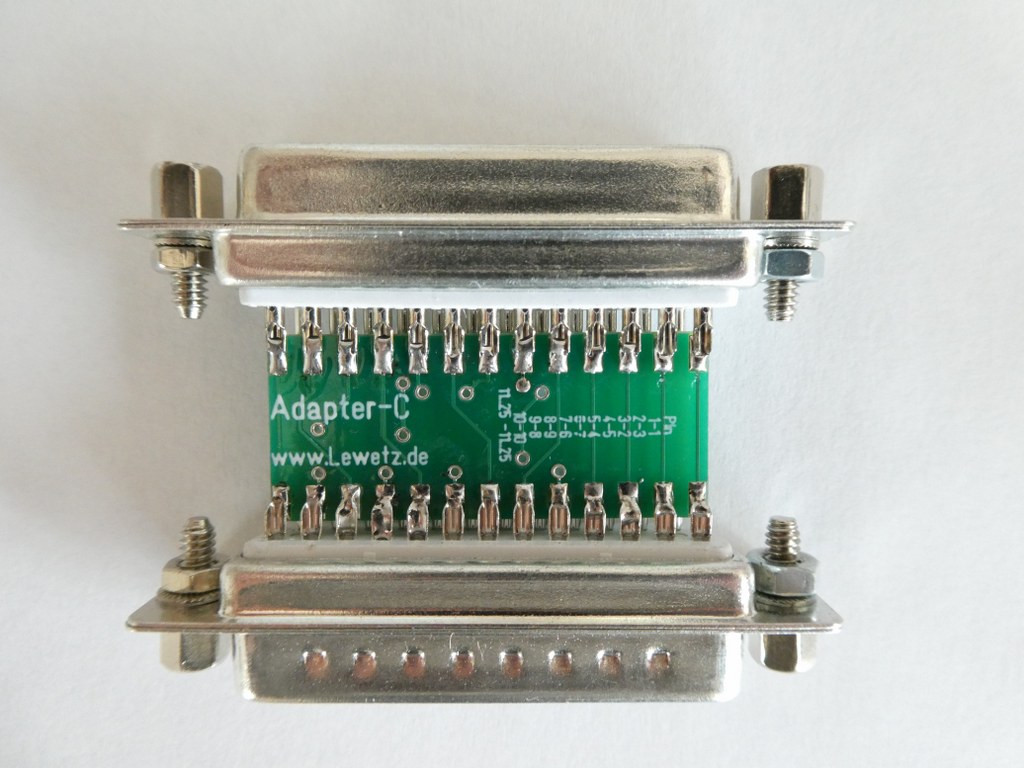

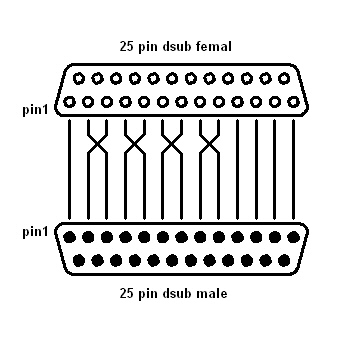

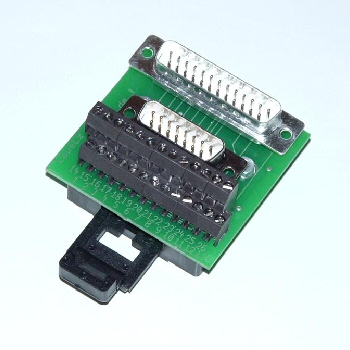

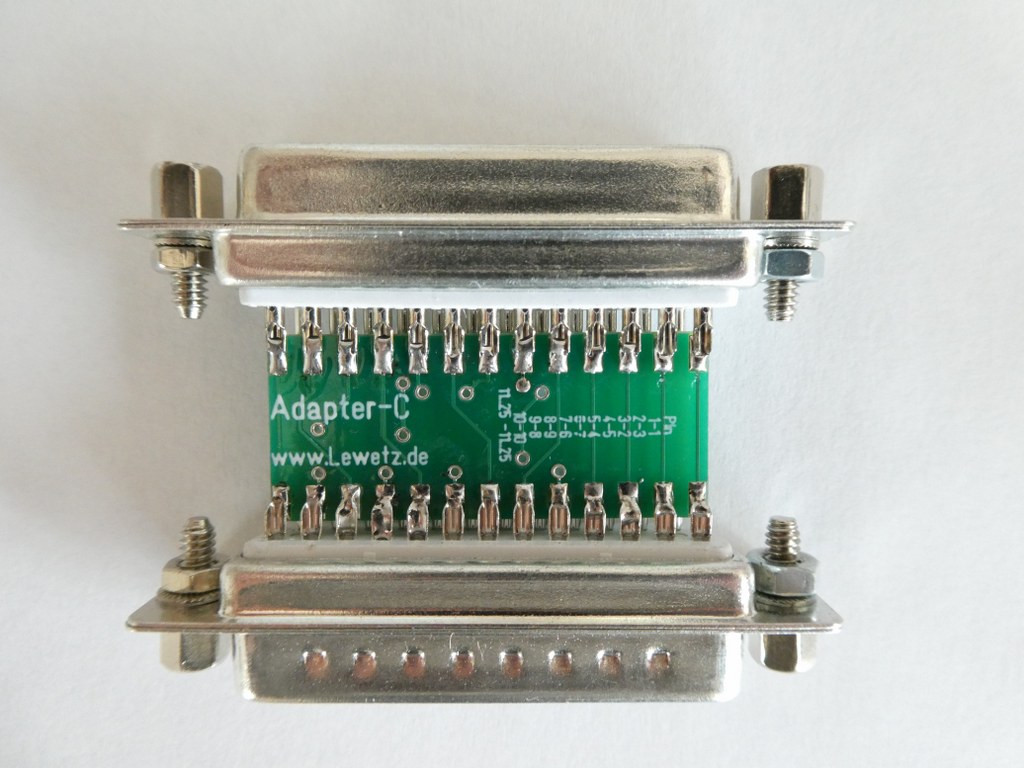

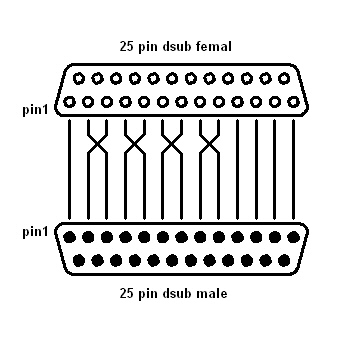

Adapter-C

Our control programs always assign the direction signals to pins 2+4+6+8 and the clock signals to pins 3+5+7+9. It might be that other control programs use an other kind of assignment, e. g. Mach3 controls clock/direction in the opposite direction in the standard assignment or in CNCProfi.

The adapter-C crosses the clock/direction signals. It could be applied for a plant which is currently running with standard assignment, e. g. Mach3 and is now to be used with WinPC-NC or if it is planned to use our stepper motor card Step3S with Mach3.

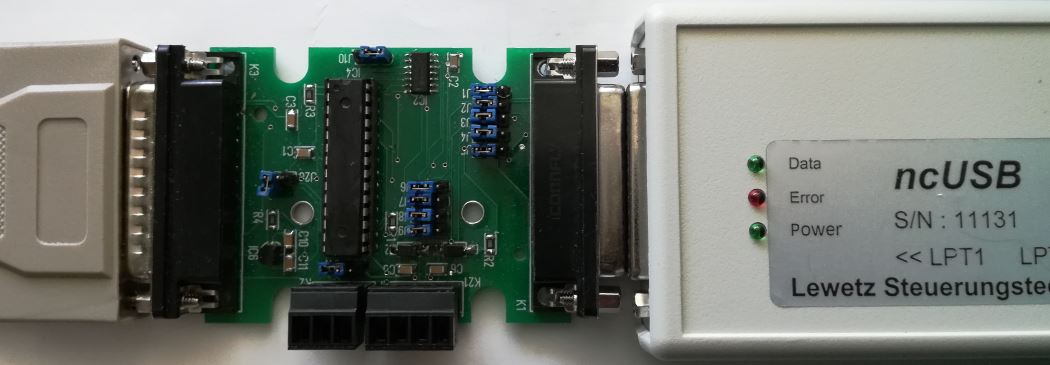

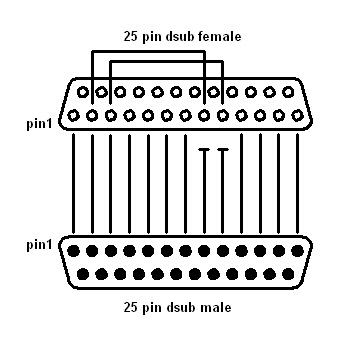

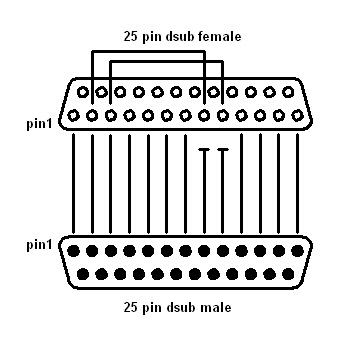

Adapter-2X

This adapter must be employed for all machines withtwo motors on the X-axis for operating them synchronously. The adapter disconnects the clock/direction signals of the 4th axis and leads the control signals of the X-axis also to thepins of the 4th axis. Thus an absolute synchronous movement of the 1st and 4th axis is obtained.

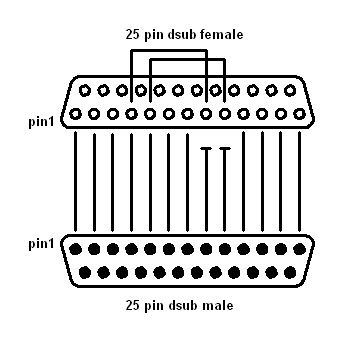

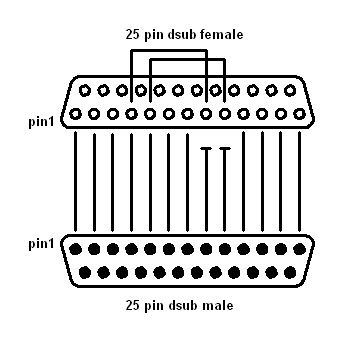

Adapter-2Y

This adapter must be employed for all machines withtwo motors on the Y-axis for operating them synchronously. The adapter disconnects the clock/direction signals of the 4th axis and leads the control signals of the Y-axis also to thepins of the 4th axis. Thus an absolute synchronous movement of the 2nd and 4th axis is obtained.

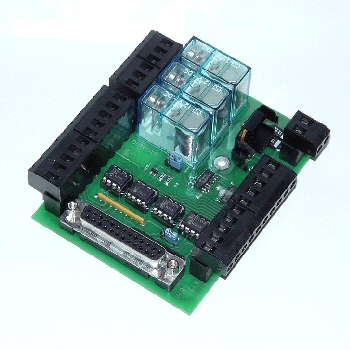

Adapter-422

This adapter converts the clock/direction signals into RS422 difference signals, e. g. as required for output stages of Berger Lahr or Siemens. Using this adapter means that there are no additional output lines but four possible inputs. Ideally it should be used in combination with the additional digital I/O card 160802 and is already included as standard in our controllers CNCCONS4 and CNCCONW4.

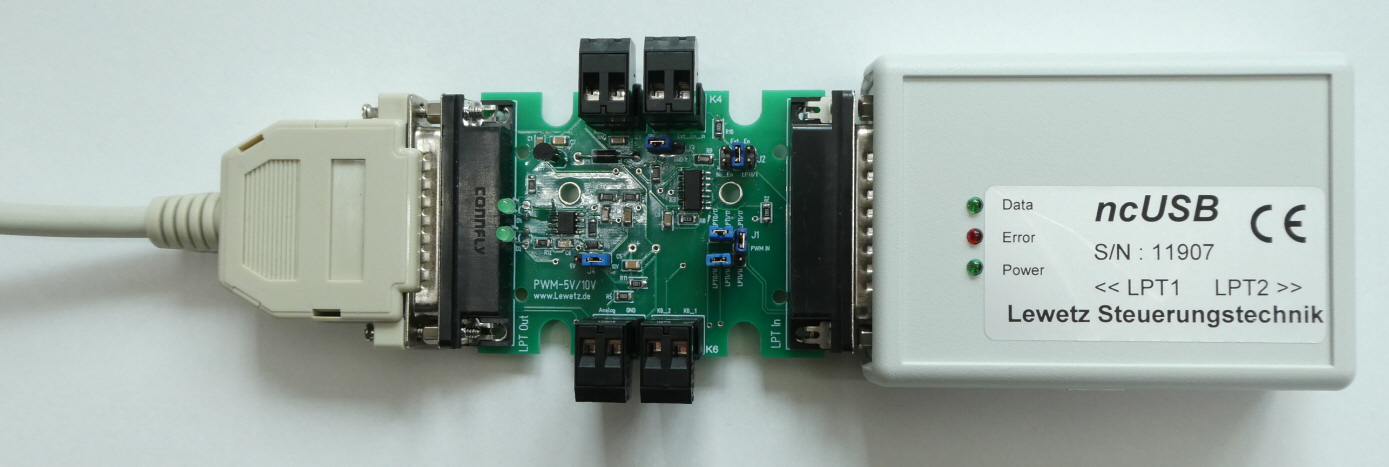

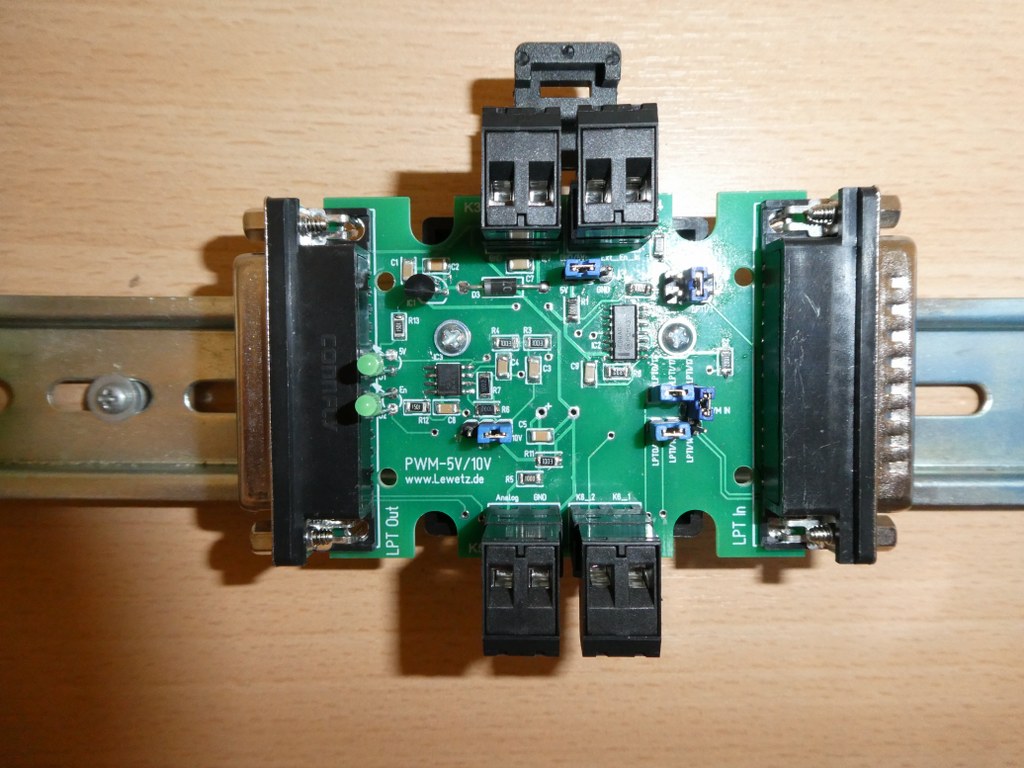

Adapter-B

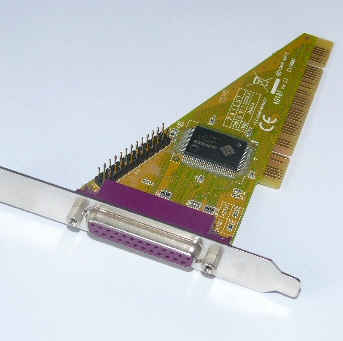

All axes controllers and Posi controllers with simple clock/pulse signals are equipped with the adapter-B as a so-called booster and ensures that there is a stable 5V level concerning all LPT output signals and an on-load voltage up to 20mA. The adapter-B can be ordered separately and retrofitted, e. g. on desktop computers at the LPT port.