PC-Posi and Posi conrollers

Our popular and well-known range of CNC control units with WinPC-NC and CNC-Control has been completed by Posi controllers. These versions are ideally suited for any kind of standard automation tasks and motion controls. Compared with path control systems with look-ahead-function, import filters and graphic display, our Posi controllers offer extremely fast point-to-point movements, a comprehensible clear text programming and a uncomplicated start-up system. CNCPOS and PosiMAX provide a control unit which is ready for operation and equipped with a powerful and efficient industrial PC hardware, an pre-installed operating system and the corresponding PC-Posi software. For the start-up procedure you need nothing but a VGA monitor and a PS/2 keyboard. After finishing the program generation and the start-up procedure all Posi controllers can be handled automatically via external input signals and all tasks are carried out in a steady, stable and reliable mode without involvement of monitor and keyboard. By using our Posi controllers you can realize any kind of handling and robot applications, feed functions, dispensing tasks, format adjustments and any other job without investing significant financial amounts. Due to distinguishing construction forms and equipments the software is most qualified for being used in various application areas. Linking-up serveral control units with mutual synchronisation via digital signals is just as practicable as the integration into larger complete systems and the coupling to PLCs or to additional subordinated controls.

Up to now, the following applications have been realized by us or our customers...

- feeding workpieces into erosion machines

- three CNCPOS controllers as interconnected system for separating and producing glass pipets with 10 axes to be controlled

- dosing and moulding of relay onto a matrix

- removing and palletising the produced workpieces from a CNC milling machine

- welding frame parts for trucks

- automatic solding of control units with base plate for domestic appliances

- bending unit with 4 axes for complex wire parts

|

|

An overview of the Posi controllers functions...

- complete mounting with control hardware in one casing

- optionally with stepper motor driver or without clock pulse/direction interface

- 4 axes up to 20KHz controllable in point-to-pointoperation, no curves and paths

- 16 octocoupled inputs and 8 optocoupled outputs, definable according to requirement

- VGA and PS/2 keyboard connection for start-up procedure or status display

- easy and intuitive operation with drop-down menus, Windows technology, hot keys, and online help functions

- program input in clear text with integrated editor, no complicated G-codes, subroutine technology, conditioned program skips, block and program selection via input and/or PLC

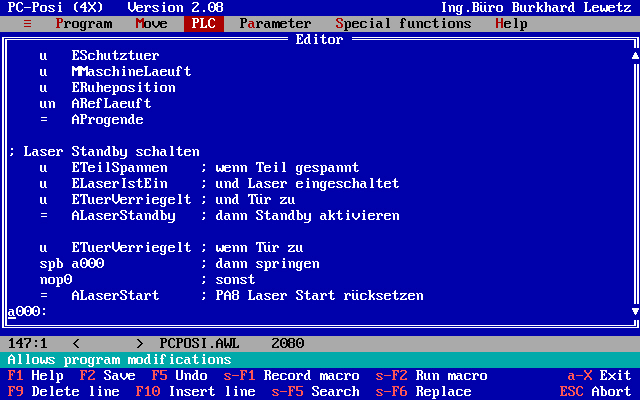

- integrated powerful and efficient soft-PLC with programming comformable to Step5

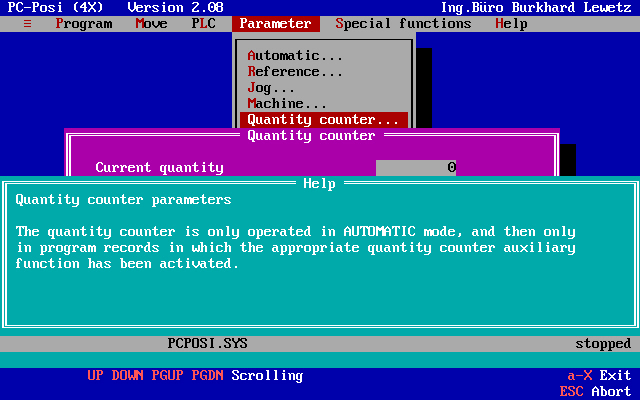

- multiple configurable parts counter

- clock times in mill. seconds

- programming device, runtime system, test and diagnostic tool and visualization in one unit, no necessity for addtitional programming station or laptop

- optionally with serial communication to other components

Easy handling and fast results

The operation of Posi controllers complies with theusual standards and besides drop-down menus, Windows technology and hot keys it also provides an extensive online help which renders assistance whenever required and which supplies useful tips. Programming can easily be understood and simply to be mastered in daily jobs.The included manual is clearly subdivided in categories and gives a detailed and comprehensible description of any kind of programming based on examples.

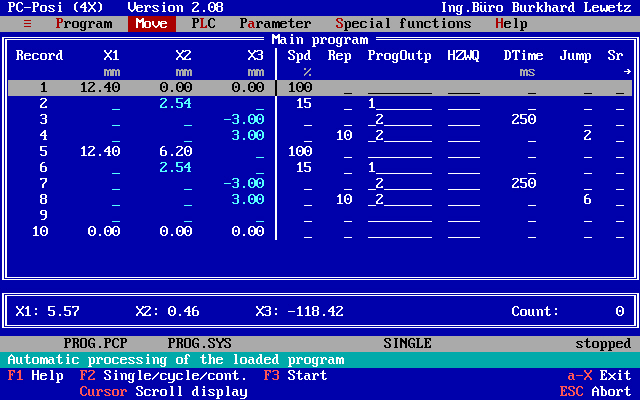

Creating and starting programs

PC-Posi organizes travelling and sequential programs as well as the corresponding parameters. Each program consists of serveral blocks which are sequentially processed in ,the automatic mode. Creating a program is made by an efficient integrated editor, which has been optimized for fast and confortable service. The program and parameters are saved and they are automatically loaded upon later re-use.

The programming of the integrated Soft-SPS can be compared with Step5 and provides more than 50 commands. Due to 256 inputs of each, outputs, flags and data items it is possible to execute more complex monitoring and controlling tasks which can run parallely to the programmed sequences and movements.

Each record may contain...

- absolute or relative distances for each axis

- speed in % to max. frequency

- repetition counter for record and block repetitions

- jump instruction and call for sub program

- dwell time at block end

- 8 outputs which are freely programmable as machine functions

- PLC flag for conditional execution or for start synchronisation

- additional functions as program stop, counter reset, reset machine and set parts counter

Automatic mode

The automatic processing of the created program is made in stand-alone, continous or in cycle operation mode, i. e. that a start command isresponsible for executing solely one block, a complete program or to carry it out endlessly. Due to complex and time-optimized programming our Posi controllers reach cycle times for a few milliseconds between the program blocks. The reaction time to the start command is also extremely short.

|

|

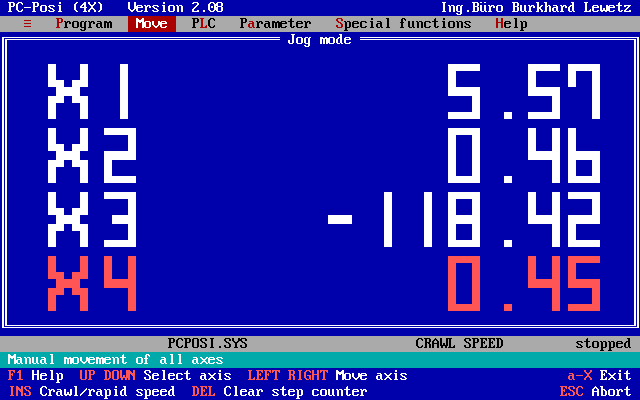

Reference run and manual setting-up

The reference run of the axes is made according to defined order and can be activated by keyboard for a single axis or for all axes. In the jog mode it is possible to move each axis via cursor key in single-step mode or using two speeds which can be setted as required. A comfortable teachin-function allows a new entry or addtional correction of programs.

The user can select various construction types and equipments of our Posi controllers

All controllers include the following components...

- efficient industrial PC mainboard with RAM and flash memory for uninterrupted continuous operation

- VGA monitor and PS/2 keyboard connection

- operating system which is ready for use and installed PC-Posi software licence for 4 axes

-

16 optocoupled inputs and 8 octocoupled outputs

- CNCPOS S3 aluminium desk-top casing with clock pulse/direction interface in 5V/TTL level

- CNCPOS S4 aluminium desk-top casing with clock pulse/direction as RS422 difference signals 5V

- CNCPOS W3 industrial casing for wall-mounting with 24V power supply and clock pulse/direction as RS422 difference signals 5V

- CNCPOS W4 industrial casing for wall-mounting with 24V power supply and clock pulse/direction as RS422 difference signals 5V

- PosiMAX3/30 desk-top casing made out of stainlesssteel with stepper motor power stages for 3 axes and up to 3A phase current

- PosiMAX4/30 desk-top casing made out of stainlesssteel with stepper motor power stages for 4 axes and up to 3A phase current

- PosiMAX2/60 desk-top casing made out of stainlesssteel with stepper motor for 2 axes and up to 6A phase current

- PosiMAX3/60 desk-top casing made out of stainlesssteel with stepper motor power stages for 3 axes and up to 6A phase current

- PosiMAX4/60 desk-top casing made out of stainlesssteel with stepper motor power stages for 4 axes and up to 6A phase current