|

WinPC-NC is a software program which turns any personal computer running the Windows operating system into a universal NC controller. Since the year 2000, WinPC-NC has delivered more than thirty thousand copies to users around the globe. Twenty languages are currently supported and more are being added. WinPC-NC is constantly being refined, upgraded, and improved. Feedback is always welcome. Quotes for custom versions and integration services will be provided upon request. |

|

|

___________________________________________________________________________________________________________________________________ |

|

Different Versions of WinPC-NC is tailored to your needs:

The WinPC-NC software and hardware components come pre-configured. Installation and setup is easy.

The standard versions of WinPC-NC are:

WinPC-NC Starter (OEM only)

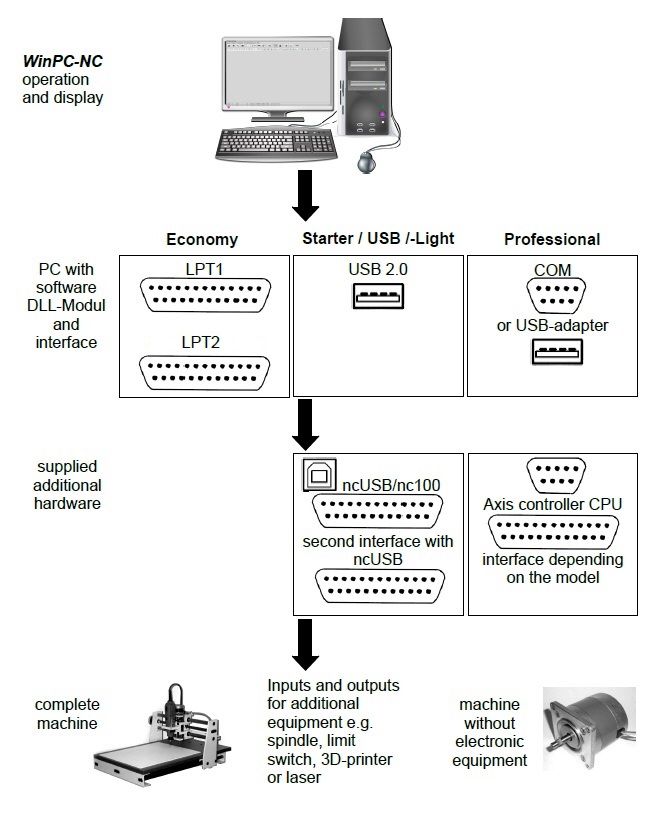

WinPC-NC Principals of Operation All versions of WinPC-NC present an identical user interface. Version changes and upgrades are transparent. The low level, specific configuration varies, based on which interface is used. Setting up signals and func-tion assignments is done once for each interface. Constructing a machine by your-self? Retrofitting a machine for NC operation? We can provide stepper motor cards, drivers, and complete control and power management systems. |

|

___________________________________________________________________________________________________________________________________

|

WinPC-NC Benefits Tuned to Your Needs WinPC-NC provides a package tuned to your needs – program features, number of axes, input/output requirements, interface requirements. A description of the various packages is given later. Possible and Realized Technologies

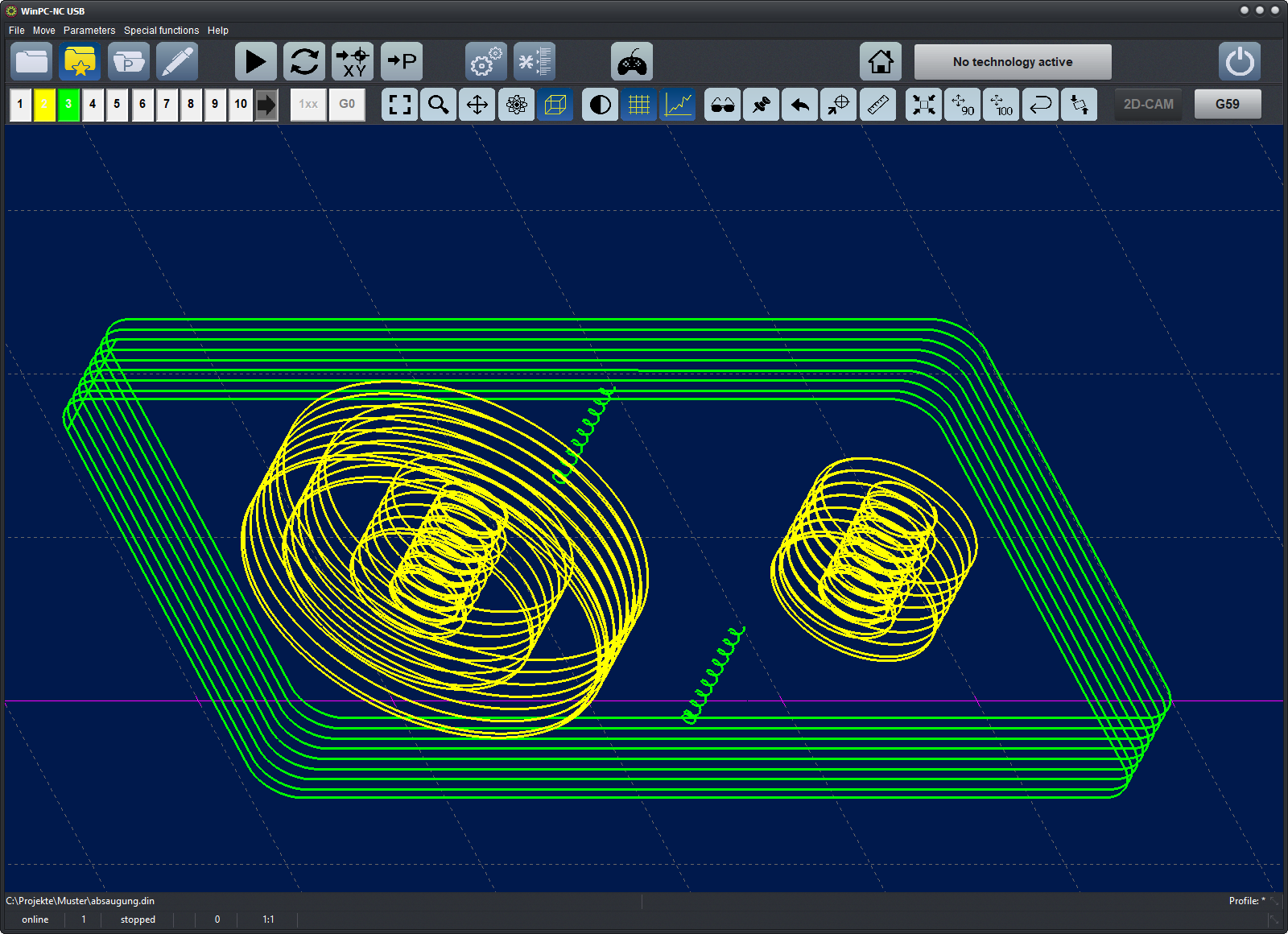

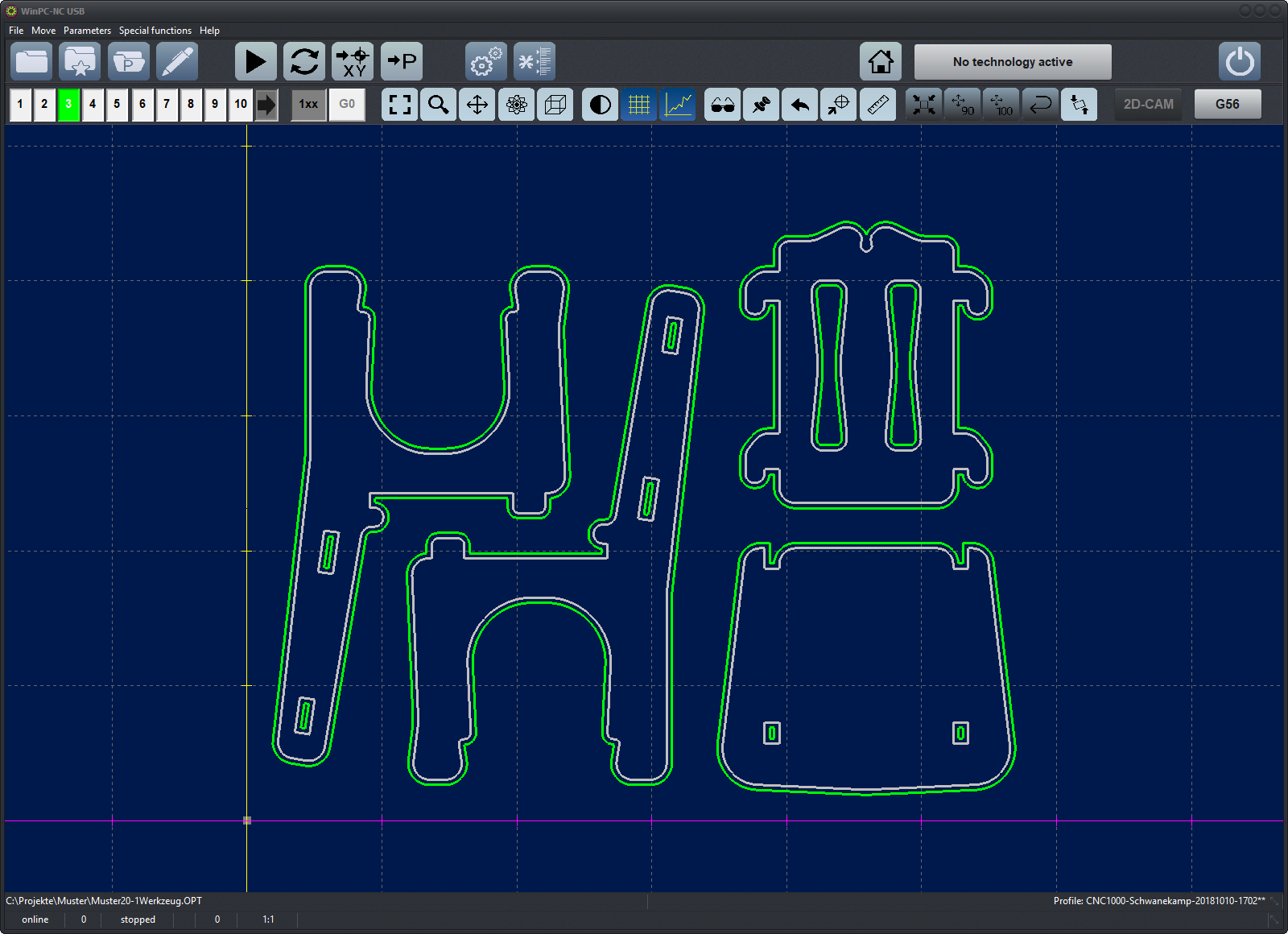

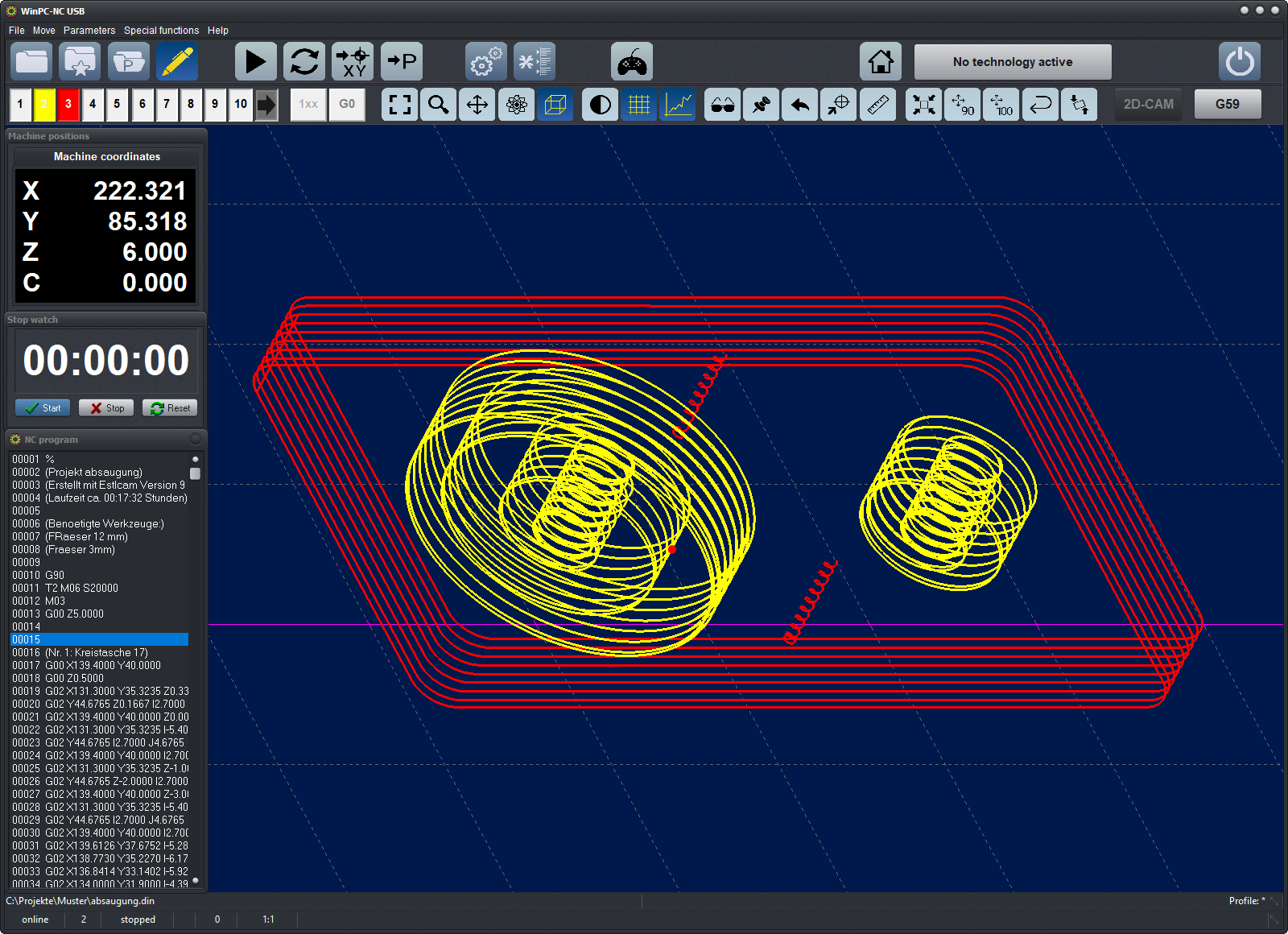

Graphical Interface The graphical interface presents the NC data in three dimensions and displays the current machine position in real time.

|

|

The data may be zoomed, rotated, and moved. Tool paths can be individually displayed or hidden. Difficult to visualize portions of the job can be viewed to ensure correctness.

Intuitive Help System WinPC-NC has a context sensitive, intuitive help system. The help best appropriate to your current action is always displayed. The help system is constantly upgraded based on customer feedback and changes in technology. Parameters and functions are closely grouped together. Setting up a machine from scratch has never been so easy!

Furthermore, the complete manual is available as a PDF file. It can also be brought up at any time from within WinPC-NC.

Adjustable Layout WinPC-NC 3.0 makes it easy for the user to create custom display templates. Color blind individuals can create a display that can see clearly. Application profiles make it easy to quickly shift from from one application to another. Multiple tool databases can easily be manipulated.

|

||||

| ___________________________________________________________________________________________________________________________________ | ||||||

NC File Format Support WinPC-NC is able to import, display, and manipulate data in numerous formats including G-Code, HPGL, DXF 2D (R12, R14), drilling formats, EPS/AI (V3, V8), DIN/ISO, Multicam, and ISEL-NCP). |

Intelligent Look Ahead System WinPC-NC is designed as a contouring seeking system. It has a powerful look-ahead capability that ensures continuous, smooth movements. A job always runs at the best possible speed. There is no stuttering or wasted motion.

2.5D CAM Functions WinPC-NC is equipped with 2.5D CAM functions. Tool diameter compensation, tool assignments, and optimization of unproductive movements are handled.

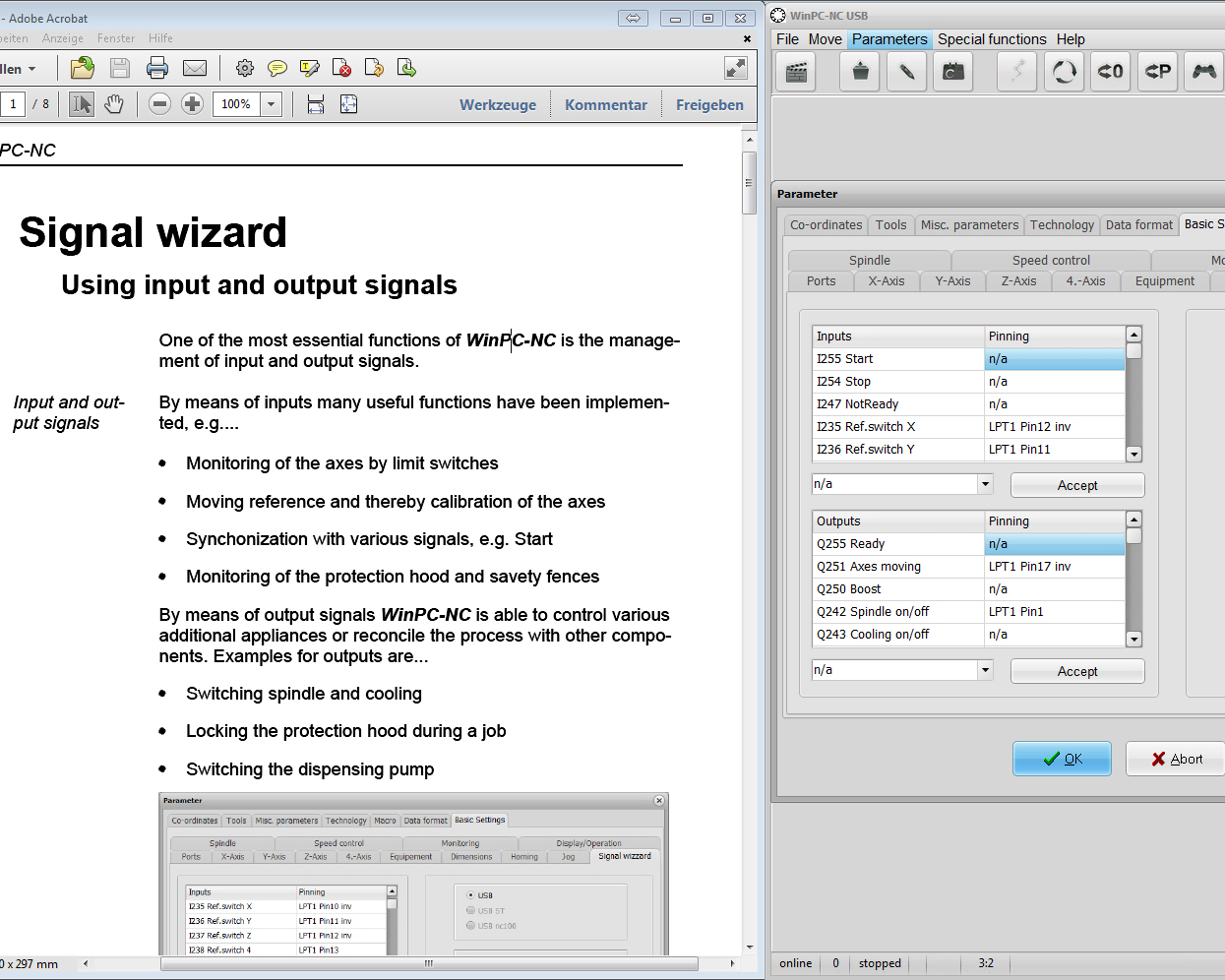

LPT Port Signal Handling WinPC-NC – depending on the interface – can manipulate all of the pins of one or two 25 pin IEEE 1284 parallel ports. Signal levels conform to the 5V TTL standard. Other functions and pins can be assigned to an appropriate input or output pin. The Signal Wizard makes it easy to understand, setup and maintain the LPT ports. |

|||||

| ___________________________________________________________________________________________________________________________________ | ||||||

|

WinPC-NC Starter for Stepcraft machines These versions are only available bundled with a machine provided by the company Stepcraft. WinPC-NC Starter is used for bringing up a new machine and its initial testing. Although limited to two tools, it is possible to engrave tags, mill, make PCBs, and mill dimensional objects. The size of the objects is unlimited. WinPC-NC Starter can be upgraded to WinPC-NC USB by obtaining a license and using the Stepcraft machine unmodified.

WinPC-NC Economy WinPC-NC Economy is a software only product. Machine control is performed via one or two IEEE 1284 parallel printer (LPT) ports. WinPC-NC Economy has additional features and is capable of 2.5, 3 and 4 axis control. It is also offered in versions which use well known SMC stepper cards. WinPC-NC Economy requires a 32-bit version of Windows 7 and is only available in WinPC-NC version 2.5. Please refer the function matrix for a detailed description of features.

WinPC-NC USB WinPC-NC USB includes a USB cable and our external ncUSB module. One or two IEEE 1284 parallel ports can be used for machine control. WinPC-NC USB is a full featured offering. It is capable of 2.5, 3, and 4 axis control. Please refer the function matrix for a detailed description of features.

|

WinPC-NC Light WinPC-NC Light includes a USB cable and our external nc100 module. One IEEE 1284 parallel port can be used for machine control. WinPC-NC Light is capable of 2.5, and 3 axis control and can be upgraded to WinPC-NC USB, with or without additional hardware. Please refer the function matrix for a detailed description of features.

Why external USB modules? The external USB modules offloads the PC from having to perform timing critical operations. This makes low overhead, very stable operation possible. |

|||||

|

___________________________________________________________________________________________________________________________________ |

||||||

|

WinPC-NC Professional WinPC-NC Professional, in conjuction with our CNCCONS controller, provides the very finest quality machine control possible. It can meet the strictest demands, both in the industrial sector or for ambitious projects. By offloading computationally intensive and timing critical operations to the CNCCONS controller, the Windows PC is free to perform other tasks while NC operations are being performed.

A CNCCONS controller can be custom configured to met any customer requirements. For example, it is possible to configure the digital inputs and outputs for industry standard 24V logic or 0-10V operation typically used for spindle speed control. Safety related sensors for doors, protection hoods, liquid levels, air pressure, physical positions, and even external components can be monitored. Each monitored sensor can have bounds established with definable warning signals generated as necessary. The CNCCONS runs a real-time operating system and offers customer accessible API routines. Commands and data can easily be generated or transmitted to other platforms (e.g. PLC controllers) and software. Customers can develop their own programs or request integration services. The CNCCONS programming manual can be provided upon request.

|

We can provide complete solutions with motor power stages in casings. The advantage is smooth and immediate interactions between all components. No complex setup procedure or signal procedures are required.

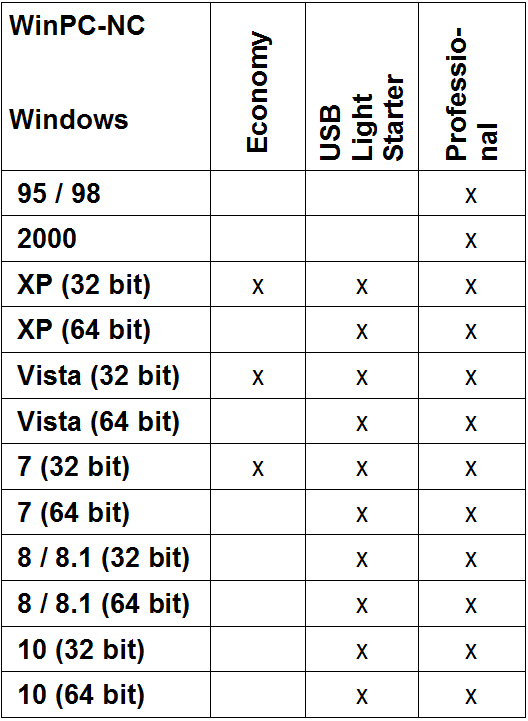

Windows Compatibility

|

|||||

| ___________________________________________________________________________________________________________________________________ | ||||||

Function Matrix

|

|

Starter |

Light |

Economy |

USB |

Prof |

|

Input/output signals and machine control |

|

|

|

|

|

|

CNC machine control |

USB 2.0 |

USB 2.0 |

LPT |

USB 2.0 |

Controller |

|

Home and limit switch pins |

5 |

5 |

10 |

10 |

up to 256 |

|

Additional outputs (spindle speed control, cooling, etc.) |

2 |

4 |

8 |

8 |

up to 256 |

|

Motor current draw monitoring, Signal boosting |

- |

√ / - |

√ / √ |

√ / - |

√ / √ |

|

Inputs/output pin definition and assignment |

- |

√ |

√ |

√ |

√ |

|

Industry standard 24V signals, optional |

- |

- |

- |

- |

√ |

|

Optional converter/adapter support for clock/direction signals |

- |

- |

- |

- |

√ |

|

Spindle speed control via a 0-10V analog output |

PWM |

- |

8Bit - PWM |

8Bit - PWM |

0-10V PWM |

|

Ready signal for safety control, toggle, charge pump - 12.5kHz |

√ |

√ |

√ |

√ |

√ |

|

Windows real time responsiveness |

best |

best |

good |

best |

best |

|

Windows background process sensitivity |

no |

no |

yes |

no |

no |

|

Maximum step rate (kHz) |

Mach.dep. |

20 |

24 |

80 |

40 |

|

Axes |

3 (XYZ) |

3 (XYZ) |

4 (XYZ |

4 (XYZ |

4 (XYZ |

|

Hardware and operating system requirements |

|

|

|

|

|

|

Supported Windows versions |

XP – Win10 32/64-Bit |

XP - Win10 32/64-Bit |

XP - Win7 32-Bit |

XP - Win10 32/64-Bit |

W95-Win10 32/64-Bit |

|

Minimum Intel/AMD processor clock speed |

>= 2GHz |

>= 2GHz |

>= 2GHz |

>= 2GHz |

>= 500MHz |

|

Peripheral ports (motherboard or ISA/PCI board) |

USB 2 |

USB 2 |

LPT / USB 2 |

USB 2 |

RS232/USB |

|

Parameter settings, machine adjustments |

|

|

|

|

|

|

Individual axis resolutions, steping, and distance/revolution data |

- |

√ |

√ |

√ |

√ |

|

Speeds, acceleration and deceleration ramps for each axis |

√ / - |

√ / √ |

√ / √ |

√ / √ |

√ / √ |

|

Testing functions (mechanical, switches, motors) |

- / - / √ |

√ / √ / √ |

√ / √ / √ |

√ / √ / √ |

√ / √ / √ |

|

Backlash compensation |

√ |

√ |

√ |

√ |

√ |

|

Input signals synchronization |

- |

- |

√ |

√ |

√ |

|

Predefined ramp profiles |

- |

- |

√ |

√ |

√ |

|

Data formats and import filters |

|

|

|

|

|

|

HPGL, PLT |

√ |

√ |

√ |

√ |

√ |

|

DXF (only 2D) (R12 and R14) |

√ |

√ |

√ |

√ |

√ |

|

Postscript, vector formats, EPS/AI (version 3 and 8) |

√ |

√ |

√ |

√ |

√ |

|

Common drilling formats including Excellon and Sieb&Meyer |

√ |

√ |

√ |

√ |

√ |

|

G code with subroutines; abs./rel. movement |

- |

- |

√ |

√ |

√ |

|

Multicam 2D and 3D, extended HPGL |

- |

- |

√ |

√ |

√ |

|

ISEL NCP |

- |

- |

√ |

√ |

√ |

|

Program functions |

|

|

|

|

|

|

CAM functions for all 2D file formats (tool diameter compensation) |

√ |

√ |

√ |

√ |

√ |

|

Intelligent look ahead for continuous, smooth movement |

√ |

√ |

√ |

√ |

√ |

|

Automatic NC file reload after a modification |

√ |

√ |

√ |

√ |

√ |

|

Contour smoothing function for perfect edges |

√ |

√ |

√ |

√ |

√ |

|

Clearance and rapid planes for safe motions |

√ |

√ |

√ |

√ |

√ |

|

Multiple language support |

√ |

√ |

√ |

√ |

√ |

|

Graphical display; zooming, rotating, moving, mirroring |

√ |

√ |

- |

√ |

√ |

|

Unlimited NC file size |

√ |

√ |

√ |

√ |

√ |

|

Machine positioning via mouse click |

√ |

√ |

√ |

√ |

√ |

|

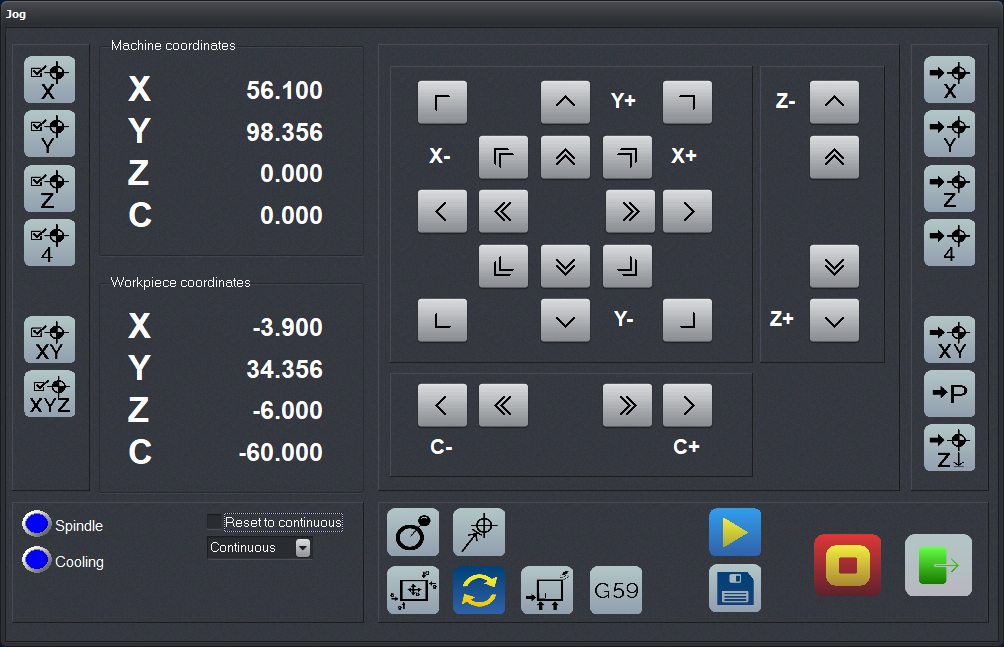

Jog in steps or predefined distances |

√ |

√ |

√ |

√ |

√ |

|

Definable job zero and park positions |

√ |

√ |

√ |

√ |

√ |

|

Maximum number of tools within a job |

2 |

10 |

10 |

10 |

10 |

|

Automatic identification of NC data |

√ |

√ |

√ |

√ |

√ |

|

Pendant (hand controller) support; integral HR-10 support |

√ |

- |

√ |

√ |

√ |

|

Integrated NC file editor |

- |

√ |

√ |

√ |

√ |

|

Switchable or simulate tool changes |

- |

√ |

√ |

√ |

√ |

|

Tool movement dwell time control |

- |

√ |

√ |

√ |

√ |

|

Signal wizard for assigning and controlling all input/output signals |

- |

√ |

√ |

√ |

√ |

|

Special display of drilling jobs |

- |

√ |

√ |

√ |

√ |

|

Machine movement button customization |

- |

√ |

√ |

√ |

√ |

|

Scaling factors for each axis |

- |

√ |

√ |

√ |

√ |

|

Metric and Imperial unit support (millimeters or inches) |

- |

√ |

√ |

√ |

√ |

|

NC program display with current line marked |

- |

√ |

√ |

√ |

√ |

|

Per tool parameter definition: characteristics, name, and color |

- |

√ |

√ |

√ |

√ |

|

Automatic Z axis feeding when following contours |

- |

- |

√ |

√ |

√ |

|

Z axis touch sensor (z zero) support (surface block) |

- |

- |

√ |

√ |

√ |

|

4th axis support (as U, ABC, T) |

- |

- |

√ |

√ |

√ |

|

Tool measurement and compensation: automatic and manual |

- |

- |

√ |

√ |

√ |

|

Tangential axis support for foil and paper cutting |

- |

- |

√ |

√ |

√ |

|

Job nesting (repetition): definable rows and columns |

- |

- |

√ |

√ |

√ |

|

Resume interrupted job – take off from where it stopped |

- |

- |

√ |

√ |

√ |

|

Cylindric engraving: diameter definition and 4th axis |

- |

- |

√ |

√ |

√ |

|

Feed rate and spindle speed override, 5% to 200% |

- |

- |

√ |

√ |

√ |

|

Software limit switches and machine dimension monitoring |

- |

- |

√ |

√ |

√ |

|

Macro programming |

- |

- |

√ |

√ |

√ |

|

Hardware home and limit switch support |

- |

- |

√ |

√ |

√ |

|

Teachin function: Manual Data Interface (MDI) for commands |

- |

- |

√ |

√ |

√ |

|

Job start from line #, percentage, or prev. cancel position |

- |

- |

√ |

√ |

√ |

|

Automatic tool change support; molette output signal |

- |

- |

√ |

√ |

√ |

|

3D part scanning |

- |

- |

- |

- |

√ |

|

Z zero determination macro (surface probe) |

- |

- |

- |

- |

√ |

|

On the fly Z height correction (inputs or keys), best for |

- |

- |

- |

- |

√ |

|

Dual X axis support; homing adjustment function |

- |

- |

- |

- |

√ |

|

Dispensing application support |

- |

- |

- |

- |

√ |

|

Automatic tool changer support, magazine monitoring sensor |

- |

- |

- |

- |

√ |

|

Definable messages with picture display for input lines |

- |

- |

- |

- |

√ |

|

Multiple head support |

- |

- |

- |

- |

√ |

|

Variois counters and timers, machine/spindle run time |

- |

- |

- |

- |

√ |

|

Packaging |

CD/dowload |

CD, cable, |

CD,USB module |

CD, cable, |

CD, cable, |

|

Manual: PDF / printed (optional) |

√ / - |

√ / - |

√ / √ |

√ / √ |

√ / √ |

Should you have further questions, require more detailed information, or would like a quote for a custom version or integration services, please do not hesitate to contact us by email (This email address is being protected from spambots. You need JavaScript enabled to view it.).

We are looking forward to your request.